Injecting Molding Services

Since the expansion of plastics into fabrication processes worldwide, injection molding has found endless popularity as a reliable approach to manufacturing. Used in making everything from simple disposable goods to complex automotive parts, injection molding’s flexibility and cost-effective qualities makes it worthy of consideration in just about any project.

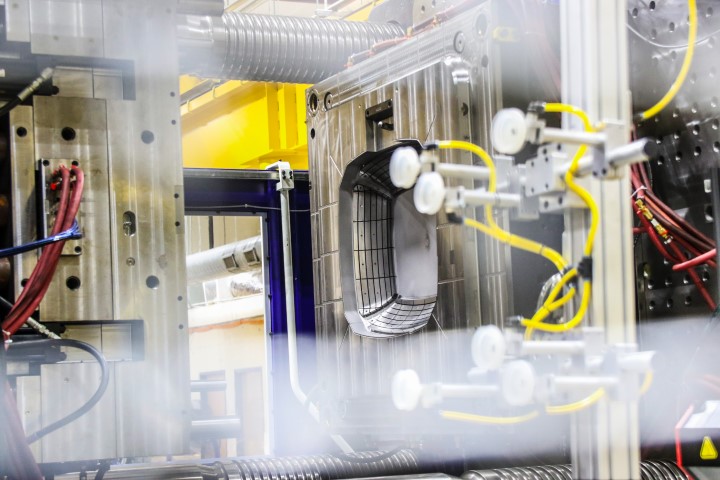

At R&D Molders, we are experts at injection molding with 40 years of experience. ISO 9001:2008 compliant and lean manufacturing specialists, we are able to mold assembly parts, small to medium parts, and multi-component products out of many polymers. In addition, our automated robotic production allows for fast output and excellent quality.

Materials we work with include common polymers such as ABS, polypropylene, polystyrene, polycarbonate, acrylic, nylon, and urethane, as well as high strength engineered polymers. Our injection molding equipment is capable of 55 to 2700 tons of force. We are also able to integrate overmolding and inserts into our injection process.

Although lead times vary on a job-by-job basis, we generally take 8 weeks to complete orders. Rush services and emergency response services are also available. We welcome orders of any volume and are open to short or long term contract runs. We are more than just a plastics molder: we can bundle value-added services with any order, such as moldmaking, inspection, machining, tooling, clean room molding, bar coding, leak testing, and many others.

To learn more about our services, see the table below or feel free to contact us directly.

Injection Molding Capabilities

| General Capabilities | Contract Consulting Custom Prototyping Turnkey Quality Control Transfer Programs Just in Time (JIT) Product Validation |

| Product Capabilities | Assembly Parts Small Parts Medium Parts Multi-Component |

| Mold Types | Insert Molding Overmolding Injection molding |

| Material | ABS Acetal EVA Acrylic Nylon Polycarbonate Polypropylene Polystyrene Polystyrene Urethane TPU TPE PPS |

| Equipment Capabilities | Automation Robotic |

| Clamping Force | Min 55 tons Max 300 tons |

| Shot Size The maximum weight of plastic that can be displaced or injected by a single injection stroke. Generally expressed as ounces of polystyrene. |

Min 2 oz Max 32 oz |

| Number of Cavities The number of cavities in the mold used to produce multiple products in one molding cycle. |

Min 1 cavities Max 16 cavities |

| Tolerance (+/-) | ±0.003" |

| Additional Services | Engineering Mold Making Machining Quality Control Lab Inspection CMM Machines Product Development Rapid Prototyping Tooling Clean Room Molding Process Monitoring In mold Labeling Leak Detection Bar Coding Inventory Control |

| Lead Time | Generally 8 Weeks Quoted on job by job basis Emergency services available Rush Services Available |

| Production Volume | Specialty Production Shop Prototype Low Volume Small Run High Volume Large Run Long Run Large Scale Production Volume Run |

Additional Information

| Industry Focus | Aerospace Automotive Building Communication Consumer Goods Electrical Electronic Maritime Medical Military Optical Industrial Consumer Goods Sporting Goods GSA/DOD Home & Garden Energy |

| Industry Standards | MAPP Manufacturers Association for Plastics Processors SPE Society of Plastics Engineers ISO 9001:2008 International Organization for Standardization UL Underwriters Laboratories FDA Registered |

| Efficiency | Lean Manufacturing |

| File Formats | AlphaCAM (AMD,ATD) AutoCAD (DWG,DWZ) BMP Bit Mapped Graphics Catia (CATDrawing,CATPart) Delcam (DGK, DMT) DXF Drawing Interchange Format, or Drawing Exchange Format GIF Graphics Interchange Format IGES Initial Graphics Exchange Specification, ANSI file format. Inventor (IDW, IPT) IronCAD (ICD,ICS) JPG or JEPG Joint Photographic Experts Group MasterCam (MDX, MC8, MC9, SET) PDES Product Data Exchange using STEP, Standard for the Exchange of Product Model Data. A standard format for exchanging data between advanced CAD and CAM programs. Portable Document Format Pro-E or Pro/Engineer (DRW,PRT,XPR) SAT 3D ACIS Model File SolidEdge (DFT) SolidWorks (SLDPRT,SLDDRW,SLDDRT) STEP Standard for the Exchange of Product Model Data SurfCam (DSN) TIFF Tagged Image File Format TurboCAD (TCW,TCX) Unigraphics (PRT) |